Blog

AI in Real-World Robotics

Share This On X:

it isn’t in any doubt that robots are getting smarter –and learning how to make better decisions-- thanks to various AI-related systems.

AI is already helping companies in the industrial, medical, agricultural and pharmaceutical sectors (among others) to stay competitive in a global marketplace dealing with COVID-19 uncertainty and widespread issues around labor availability –and A3 members are leading the way.

While experts debate the finer points of what constitutes a true general artificial intelligence (AI) and the various steps that can get us there, it isn’t in any doubt that robots are getting smarter –and learning how to make better decisions-- thanks to various AI-related systems.

From the autonomous cars on our roads and the autonomous mobile robots in the world’s warehouses through to AI-powered machine vision systems, edge computing in manufacturing environments, and agricultural drones that can process huge amounts of data on the fly, AI greatly enhances robot performance by providing bots with intelligent decision-making capabilities based on an analysis of billions of data points coupled with neural network and deep learning strategies. Crucially, AI enables robots to be more flexible, while at the same time enhancing traceability across all types of automation processes.

Along with Big Data and the Internet of Things, AI is a crucial element of Industry 4.0 and 5.0. AI is already helping companies in the industrial, medical, agricultural and pharmaceutical sectors (among others) to stay competitive in a global marketplace dealing with COVID-uncertainty and widespread issues around labor availability –and A3 members are leading the way.

Just this week, Soft Robotics Inc announced that it has raised USD10 million to expand commercial operations and support the launch of a range of ‘SoftAI’ powered robotic solutions. SoftAI layers 3D vision and AI on top of soft grasping hardware to enable the automation of bulk picking processes, such as bin picking in the food supply chain.

Also this week, Ambi Robotics, makers of the AI-powered AmbiSort robotic sorting system, announced a partnership with DWFritz Automation to build custom robotic solutions for supply chain customers. AmbiSort is a configurable robotic sorting system that can sort and pack millions of unique parcels, such as boxes, polybags and envelopes, into destination containers around 50% faster than manual systems. AmbiSort runs on AmbiOS, an operating system that leverages proprietary simulation-to-reality AI to enhance robot performance.

Elsewhere, Neurala recently announced USD12 million in funding to advance the development and spread of its VIA Software --an integrated, AI-powered software solution that’s designed to help manufacturers improve quality inspection processes on the production line.

Meanwhile, GreyOrange Inc. has developed an order ‘Fulfilment Operating System’ that combines AI and mobile robots to decide on and execute warehouse activities, based on customer requirements. Leveraging the company’s GreyMatter AI software, the system uses predictive and real-time data around orders, promises, inventory, shipping windows, and resources to determine how workers and robots work can best collaborate to optimize order fulfilment processes. In March, GreyOrange and California-based AI robotics integrator Vicarious launched the Autonomous Vertical Picking system, which is designed to automate pick-n-pack operations in omnichannel fulfilment.

A global leader in developing products at the intersection of AI and robotics, NVIDIA offers the Jetson AGX Xavier Platform, which is designed to provide autonomous vehicles with the AI needed to perceive their environment, control movement, and make intelligent decisions.

The Cainiao XG ALV is just one example of an autonomous vehicle that’s using NVIDIA’s Jetson AGX Xavier Platform as its main computing unit. Combining this AI platform for embedded edge computing and with additional help from NVIDIA’s TensorRT and TensorFlow products, the vehicle is able to continuously optimize its deep learning models through testing, development, and deployment. This is no mean feat given that the autonomous vehicle is equipped with a wide range of sensors (including lidars, cameras, GPS, and inertial measurement units), that continuously generate billions of data points. AI is crucial to the safe and effective deployment of autonomous vehicles on our roads and in other public spaces.

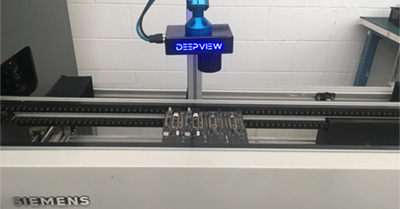

In March, Mt. Clemens, MI-based, DeepView Corp. released the X-400, an AI-powered smart camera that supports on-board training, deployment, and storage. The camera comes with a 400 Core GPU designed to allow full resolution image processing and 3 CPUs capable of handling 12 trillion operations a second –exactly the type of resolution and computing power that’s required for training neural networks. All the hardware is provided on-board the camera, eliminating the need for an external server/PC during initialization and deployment. Additionally, the DeepView AI Camera enables production inspection and new application training using an intuitive web-browser interface.

In March, Mt. Clemens, MI-based, DeepView Corp. released the X-400, an AI-powered smart camera that supports on-board training, deployment, and storage. The camera comes with a 400 Core GPU designed to allow full resolution image processing and 3 CPUs capable of handling 12 trillion operations a second –exactly the type of resolution and computing power that’s required for training neural networks. All the hardware is provided on-board the camera, eliminating the need for an external server/PC during initialization and deployment. Additionally, the DeepView AI Camera enables production inspection and new application training using an intuitive web-browser interface.

AI has penetrated robotics to such an extent that even domestic robot vacuum cleaners are make use of it to enhance learning and performance. For example, Samsung Electronics recently released the Jet Bot AI+ in Europe and the U.S. Powered by Intel’s Mobidius AI solution, the cleaning bot arrives per-trained on more than one million images, enabling advanced object recognition and improved performance.

A3 has launched a new Artificial Intelligence Technology Strategy Board as part of a major initiative to promote education and adoption of the applications of artificial intelligence in automation industries. Find out more at A3’s Artificial Intelligence Portal.

Recent Posts

- Automate Logistics Processes with K.Hartwall’s A-MATE™ AGVs

- Unlocking Potential: How the CHIPS Act Fuels Semiconductor Expansion for Automation and Beyond

- Looking at the Latest Machine Vision Standards Updates

- Insights into Robotics & Automation Investment Trends Emerging in 2024

- Hyperspectral and Multispectral Remote Sensing in Industrial Automation

- Powering Precision: Smart Linear Motors in Industrial Automation

- View All