Industry Insights

When to Choose a Multispectral or Hyperspectral Camera (or Both) for Fruit Inspection

POSTED 04/27/2021 | By: Jimmy Carroll, A3 Vision & Imaging Editoral Contributor, Tech B2B

Multispectral and hyperspectral imaging are two primary methods for capturing images with higher spectral resolution than human color perception. Hyperspectral imaging involves narrow, usually contiguous spectral bands, including possibly hundreds or thousands of spectra, while multispectral imaging involves spectral bands of varying bandwidths — not necessarily contiguous. Multispectral imaging can be thought of as a reduced subset of hyperspectral imaging. These two complementary technologies do not compete with one another, so choosing between them comes down to application requirements.

Battle of the Bands

Oftentimes when an end user knows the spectral signature of an object to be identified or distinguished going into certain applications, multispectral imaging can help. Methods for multispectral imaging vary. They include deploying dedicated LED lighting with monochrome cameras, multi-bandpass filters, spectrometers, prisms, filter wheels, or tunable filters into a machine vision system. Multiple filters or specialized sensors can also be integrated with a camera for spectral imaging. For example, Allied Vision’s new Goldeye cameras with Sony SenSWIR image sensors support thermoelectric cooling to enable reproducible imaging results — an especially important feature for distinguishing small signal differences, said Jens Hashagen, business development manager for SWIR at Allied Vision.

Oftentimes when an end user knows the spectral signature of an object to be identified or distinguished going into certain applications, multispectral imaging can help. Methods for multispectral imaging vary. They include deploying dedicated LED lighting with monochrome cameras, multi-bandpass filters, spectrometers, prisms, filter wheels, or tunable filters into a machine vision system. Multiple filters or specialized sensors can also be integrated with a camera for spectral imaging. For example, Allied Vision’s new Goldeye cameras with Sony SenSWIR image sensors support thermoelectric cooling to enable reproducible imaging results — an especially important feature for distinguishing small signal differences, said Jens Hashagen, business development manager for SWIR at Allied Vision.

Companies like Smart Vision Lights support the use of these sensors in multispectral imaging applications by offering combined SWIR + UV + visible LED-based machine vision lights that complement Sony IMX990 and IMX991 SenSWIR sensors as well as the quantum-dot SWIR Vision Systems’ colloidal quantum dot (CQD) sensor line.

“By offering lights with SWIR, visible, and UV wavelength LED combinations — ranging from 365 nm to 1750 nm — Smart Vision Lights aims to help systems integrators realize the full potential of cost-effective, multi-wavelength multispectral imaging systems,” said Jeremy Brodersen, optical engineer at Smart Vision Lights.

Hyperspectral imaging is a method for gathering a comprehensive spectral data cube that can be analyzed at a later time for applications such as the remote sensing of soil or vegetation. However, the technology has evolved from an exploratory scientific technology into something that can adapt to different types of material streams and operational environments. Today, hyperspectral cameras can identify and help sort materials with different chemical contents or measure quality parameters of materials, according to Katja Lefevre, head of applications at Specim.

“Fat and protein have very distinctive spectral features in the NIR range but cannot be measured in the visible range, for example” said Lefevre. “Specim cameras specifically targeting demanding industrial applications provide the ability to identify potential foreign objects and to simultaneously measure protein and fat content, for example.”

Complementary Technologies

Hyperspectral imaging is also an ideal option when spectral requirements of an application are not known or are very complex (for example, when they are beyond the capability or cost benefits of typical multispectral imaging sensors), according to Matthias Sonder of advanced and business development at Teledyne Imaging, a company that offers several multispectral cameras, including line scan models with two to eight spectral bands.

Hyperspectral imaging is also an ideal option when spectral requirements of an application are not known or are very complex (for example, when they are beyond the capability or cost benefits of typical multispectral imaging sensors), according to Matthias Sonder of advanced and business development at Teledyne Imaging, a company that offers several multispectral cameras, including line scan models with two to eight spectral bands.

“The limitations of multispectral imaging are the strengths of hyperspectral imaging, and vice versa,” he said. “Hyperspectral imaging will always be the go-to for exploratory work, where speed, cost, and complexity matter less, and multispectral imaging systems are the natural derivative of that exploration once a production system needs to be built.”

However, it is important to note that many machine builders in the sorting industry deploy hyperspectral cameras that deliver the ability to help sort high quantities of materials per hour with high accuracy, suggested Lefevre.

In an application such as fruit inspection, for example, hyperspectral imaging analysis can isolate the three to five spectral channels that best serve the inspection system, according to Rich Dickerson, marketing communications manager at JAI.

Fruit Inspection

Both multispectral and hyperspectral imaging technologies suit food inspection applications quite well but do so in different ways. A machine vision system may inspect fruits such as blueberries, apples, or strawberries for quality. Tasks like these can be done by focusing in on specific bands in the RGB and near-infrared (NIR) bands.

Both multispectral and hyperspectral imaging technologies suit food inspection applications quite well but do so in different ways. A machine vision system may inspect fruits such as blueberries, apples, or strawberries for quality. Tasks like these can be done by focusing in on specific bands in the RGB and near-infrared (NIR) bands.

In the visible channel, the system can look at surface defects and then use 760 or 780 nm LEDs in the first NIR band to identify the contour of fruits and spot difficult-to-see bruises on fruits like blueberries, for example. Then a band with 850 or 940 nm LEDs can look for ripeness and moisture content. JAI’s Flex-Eye multispectral prism-based camera allows customers to view three video streams from the same optical axis at high speeds, in a single pass and at high resolution, said Paritosh Prayagi, director of product management at JAI.

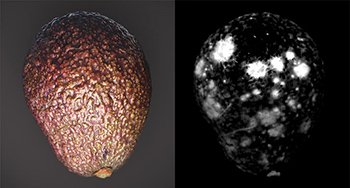

On the other hand, certain food inspection applications go beyond the capabilities of multispectral imaging. For example, avocado inspection involves a very detailed analysis of fat content, a task that suits hyperspectral imaging technology quite well.

“Identifying the ripeness of an avocado is difficult to do with limited information,” said Prayagi. “This application involves a depth of data in order to come to a quantitative analysis of the fruit, which really requires a lot of bands.”

Harvesting avocados at optimum maturity is important to ensure a high-quality fruit. The fruit’s price is higher at the beginning of the picking season, however, so harvesters may be tempted to pick immature fruits that will not properly ripen. As a result, an avocado’s taste and nutritional value will suffer. On the other hand, an overmature avocado picked too late has a shorter shelf life and has an added risk of disease. Predicting avocado quality is difficult, but cameras such as those from Specim can detect and predict changes not visible to the naked eye. Prediction models can then be built and applied to detect fruits and their parts that are at highest risk of spoiling. These cameras operate in ranges including SWIR, VNIR, NIR, and MWIR and include the FX10 (400 to 1000 nm) and FX17 (900 to 1700 nm). They can also help sort foreign objects from food.

Making a Choice

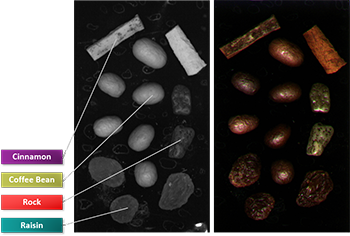

When it comes to deciding whether to use a multispectral or a hyperspectral camera for a given application — or both — it comes down to the level of data that already exists. If the system integrator or end user knows that there a select number spectral bands that will provide the highest level of detail for inspection or analysis, multispectral imaging will fit. In scenarios that require more spectral bands than multispectral imaging can provide, hyperspectral imaging suits the job. Additionally, when a user does not know the spectral requirements of an application or wants to gather a data cube that can be analyzed later, hyperspectral imaging technology can help.

In scenarios where a farmer may introduce new fruits that require inspection, deploying both options might make sense. The hyperspectral camera can identify the optimal spectral channels, and the multispectral camera can perform the higher-speed inspection in those bands.