Blog

Catching the Wave of the Industrial Internet of Things

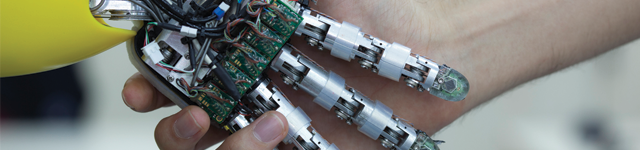

A new technology wave is gaining momentum and analysts are saying its impact will create another industrial revolution. Machines connected to each other will share information that will boost global productivity. Cloud-based solutions will drive automation and productivity.

Small to medium manufacturers who are new to industrial automation might be tempted to ignore the grand promises made by consulting firms and larger corporations who have millions to invest in developing technologies.

Keeping your eye on how the Industrial Internet of Things (IIOT) is developing can be a smart move, preparing you to make your operations as efficient and profitable as possible. Don't get swayed by the hype. Understand the benefits and risks to your business.

Seeing IIOT in Action

Machine-to-machine communication will lead to money-saving decisions and improve productivity. Companies can use the data to strengthen relationships with their customers like making guarantees that would not have been possible.

Some are calling this an "outcome" economy with results that could range from guaranteed energy savings in commercial buildings to guaranteed crop yields. An airline could reward suppliers for improved performance and reduced passenger delays. Data can automatically schedule maintenance and order spare parts while a plane is still in flight.

An article on the website motioncontrolonline.org acknowledges that companies want to see case studies before spending money to enhance communications among robots or cull data.

The write-up, Industrial Internet of Things: Sifting Reality from Hype, described a clear example of the IIOT's benefits in a world-class mining operation.

Mining Case Study

In a factory, robots act as mobile sensor platforms. Transform this platform outdoors using some of the world's largest dump trucks. Australian mining company Rio Tinto in cooperation with the University of Sydney automated a fleet of trucks with 32 sensors embedded in the engine block, up to 120 sensors in the drivetrains, and 40 in the wheels. Up to 4.9 terabytes of data were generated daily.

Human drivers weren't needed since the sensors tracked conditions and controlled speed and locations. The position sensors guided the trucks on the shortest route and saved on fuel consumption. The sensors also provided data for preventative maintenance.

Rio Tinto's conclusion was that connectivity provides opportunities to improve in all phases of an operation.

Concerns

A manufacturing company's executive team tracking expenditures and profits may remain content with their flexible or fixed cell robots operating on the factory floor. Why invest in something new when what you have is working just fine?

Challenges facing the widespread use of IIOT are similar to the pattern that existed for the development and lifecycle of computer technologies.

Monstrous stand-alone corporate machines run by specialists gave way to mainframe networks. Personal computing was the next phase and mobile devices like today's smartphones brought even more personalization. The technology became more portable, more affordable, and easier to use.

There are barriers to overcome and companies don't want to risk capital on concepts that are not proven effective. Real costs surround efforts to implement new technology.

Multinational corporations can earmark money that smaller manufacturers can't afford. Security concerns exist about hackers being able to interfere with systems, retrieve data and manipulate machinery. A facility's infrastructure has to be able to support full-scale connectivity.

Breaking Down the Barriers

Benefits for integrating the IIOT into daily operations include greater asset utilization, employee productivity and a more favorable customer experience.

As noted in Robotics 2015 and Beyond: Collaboration, Connectivity, Convergence the Internet of Things technologies will drive and transform manufacturing operations.

Based on decades of improving the user experience across a digital platform, the IIOT transformation isn't a question of if it might happen, but when usage will become widespread.

Once prices are within reach for most of the market, there is greater ease of use, and companies begin reporting how they improve operations then the technology will become a necessary part of our working lives.

Stay informed on market data and trends for your own decision making by visiting the Resources page of motioncontrolonline.org.

Recent Posts

- Automate Logistics Processes with K.Hartwall’s A-MATE™ AGVs

- Unlocking Potential: How the CHIPS Act Fuels Semiconductor Expansion for Automation and Beyond

- Looking at the Latest Machine Vision Standards Updates

- Insights into Robotics & Automation Investment Trends Emerging in 2024

- Hyperspectral and Multispectral Remote Sensing in Industrial Automation

- Powering Precision: Smart Linear Motors in Industrial Automation

- View All